The Fraunhofer Institute for Solar Energy Research ISE and NWO Institute AMOLF have developed a multijunction solar cell with an efficiency of 36.1%, beating the record of 29.4% efficiency silicon-based solar cells.

The multijunction solar cells with multiple layers of light-absorbing materials stacked on top of each other allow each layer to capture specific segments of the sunlight’s color spectrum efficiently. The solar cell combines a “silicon TOPCon” solar cell, a novel high-efficiency cell with two semiconductor layers composed of gallium indium phosphide (GaInP) and Gallium Indium Arsenide Phosphide (GaInAsP). The layer stack is further coated with metal/polymer nanocoating. The back reflector incorporated into the design enhances light trapping within the solar cell, marking the first time efficiency has been pushed beyond the 36% milestone.

The cell was unveiled at the European Photovoltaic Solar Energy Conference in Lisbon. The ultra-high-efficiency multijunction cells are more expensive to produce than conventional 27%-efficiency silicon solar cells. They are useful in scenarios where space is limited and substantial solar power generation is essential., such as solar-powered electric cars, consumer products, and drones.

New single-atom catalysts could boost RE storage

A team of researchers from City University Hong Kong (CityU) and Imperial College London designed and tested a way to store renewable energy as hydrogen using a new catalyst based on single atoms of platinum. This is done by using renewable energy to split water molecules into hydrogen and oxygen, with the energy stored in the hydrogen atoms. This method then uses platinum catalysts to spur a reaction that splits the water molecule, which is called electrolysis. While platinum is an excellent catalyst for this reaction, it is also expensive and rare. So, in order to cut down system costs and limit platinum extraction, it is critical to minimise its use.

The good news is that now researchers have designed and tested a catalyst that uses as little platinum as possible to produce an efficient but cost-effective platform for water splitting. The team’s innovation involves dispersing single atoms of platinum in a sheet of molybdenum sulfide (MoS2). This uses much less platinum than existing catalysts and even boosts the performance, as the platinum interacts with the molybdenum to improve the efficiency of the reaction. Moreover, to use the stored RE as electricity, the stored hydrogen again needs to be converted using fuel cells, which produce water vapor as a by-product of an oxygen-splitting reaction. The team said used a single-atom catalyst for this reaction that is based on iron, instead of platinum, which could further reduce the cost of this technology. When scaled, this solution can be a game changer for saving renewable energy as hydrogen, to be stored and transported for later use.

New design to use 40% of the sun’s heat to produce clean hydrogen

The engineers at the Massachusetts Institute of Technology (MIT) have laid out the conceptual design for a system that can efficiently produce “solar thermochemical hydrogen.” According to research published in Solar Energy, the technology uses the sun’s heat to split water directly and produce hydrogen, a clean fuel that can run ships, vehicles and planes over long distances without producing any greenhouse gas emissions. Currently, the majority of the procedures used to manufacture hydrogen include the usage of natural gas and other fossil fuels, which turns the normally environmentally friendly fuel into a “grey” energy source when taking into account all aspects of its life cycle.

In contrast, solar thermochemical hydrogen, or STCH, offers a totally emissions-free alternative, using only renewable solar energy to produce hydrogen. However, so far, existing STCH designs have limited efficiency with only about 7% of incoming sunlight being used to make hydrogen, giving low-yield and high-cost results. It is estimated that the new design proposed by the MIT team could harness up to 40% of the sun’s heat to generate that much more hydrogen, decreasing the overall cost of the system and making STCH a potentially scalable and cost-effective solution to aid in the decarbonization of the transportation sector. A concentrated solar plant (CSP), which consists of a circular array of hundreds of mirrors that gather and reflect sunlight to a central receiving tower, would be used in the MIT system to provide solar heat. The heat from the receiver is then absorbed by an STCH system, which uses it to split water and create hydrogen. This is not the same as electrolysis, which splits water by using electricity rather than heat.

One-atom thick nanoribbons to enhance efficiency in batteries and solar cells

Researchers at University College London (UCL) have designed one-atom-thick phosphorous ribbons alloyed with arsenic. These ribbons have the potential to significantly increase the efficiency of devices like solar cells, supercapacitors, and batteries. The research team discovered phosphorus nanoribbons in 2019. Predicted to revolutionise devices ranging from batteries to biomedical sensors, it has since been used to increase lithium-ion battery lifetimes and solar cell efficiencies. However, phosphorus-only materials do not conduct electricity very well, hindering their usage for certain applications. But recently, the team created nanoribbons made of phosphorus and tiny amounts of arsenic, which they found were able to conduct electricity at temperatures above -140°C, while retaining the benefits of the phosphorus-only ribbons.

According to the researchers, their work on alloying phosphorus nanoribbons with arsenic offers up new possibilities, including boosting near-infrared detectors used in medical applications and improving energy storage in batteries and supercapacitors. Arsenic-phosphorus nanoribbons also have the potential to increase the efficiency of solar cells by optimising the charge flow across the devices.

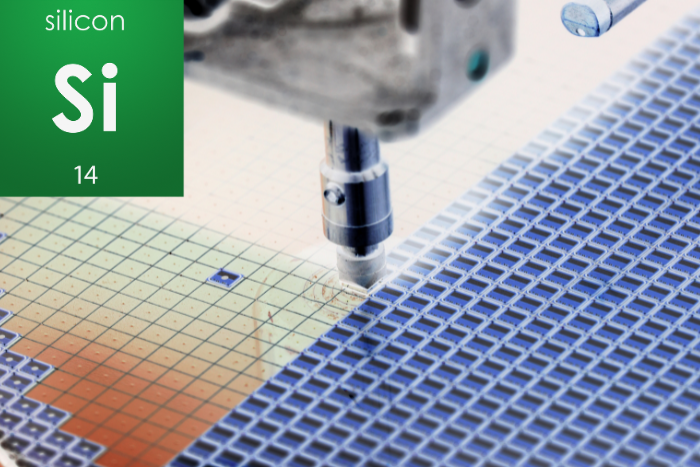

Indian business, Gautam Solar, granted patent for innovation in PV module production

India-based company Gautam Solar has been granted a patent for a “tool for the bussing process of solar panels”. The creation of a tool for the bussing of solar panels was granted the patent by the Office of the Controller General of Patents. At a fraction of the price of an automatic machine, the patented tool provides a number of benefits to module makers, including a decrease in manual labour of over 50% and a doubling of solar panel manufacturing capacity.

The tool also reduces warpage, fracture, and thermal stress in solar cells, which significantly lengthens the lifespan of the panel. The tool also reduces human error and vastly increases precision in the manufacturing of solar panels. It offers precise control for soldering in accordance with specifications for solar panel installation and operates without a hitch within a temperature range of 300°C to 450°C. The device also has a special connection structure that guarantees even thermal energy distribution and relieves pressure on solar cells, where temperature control can be done precisely with a thermocouple probe.

About The Author

You may also like

First EV battery plant launched in Indonesia, the country with largest nickel reserve

India can climb the global battery supply chain ladder. Here’s how.

New safety standards for EVs in India released

New method to produce hydrogen uses solar energy, agricultural waste

Tata Power-DDL to demonstrate vehicle-to-grid technology in North Delhi