In the second part of the series on production-linked initiatives (PLIs) in the renewables sector, CarbonCopy analysed the PLIs of solar and batteries to check their effectiveness, but this threw up more questions than answers

As the first part of this series said, India is trying to become a manufacturing powerhouse in a clutch of old and new sectors.

Its timing is propitious. After COVID-19, countries don’t want too much geographical concentration in their supply chains. They seek an alternative to China.

In tandem, in a clutch of emerging sectors like batteries, semiconductors and electrolysers, countries are jockeying for dominance. Hitherto energy importing countries are vying to become exporters—of new technologies, the equipment used to produce renewable energy, or the energy itself.

India is hoping to capitalise on both trends. Its policy instrument, however, is a tad untested. The production-linked incentive scheme, as the first part of this series said, stands on three pillars—a disability cost it will pay manufacturers to offset losses due to India’s lack of manufacturing competitiveness; a focus on creating a few champions in each sector where India wants competitive advantage; and atmanirbharta, or maximal localisation in each value chain to reduce dependence on other countries.

Much of this is a departure from previous efforts to boost India’s manufacturing competitiveness. To understand if PLI will help India create the technological leaders of tomorrow, CarbonCopy studied the PLIs for solar and batteries.

What the solar PLI tells us

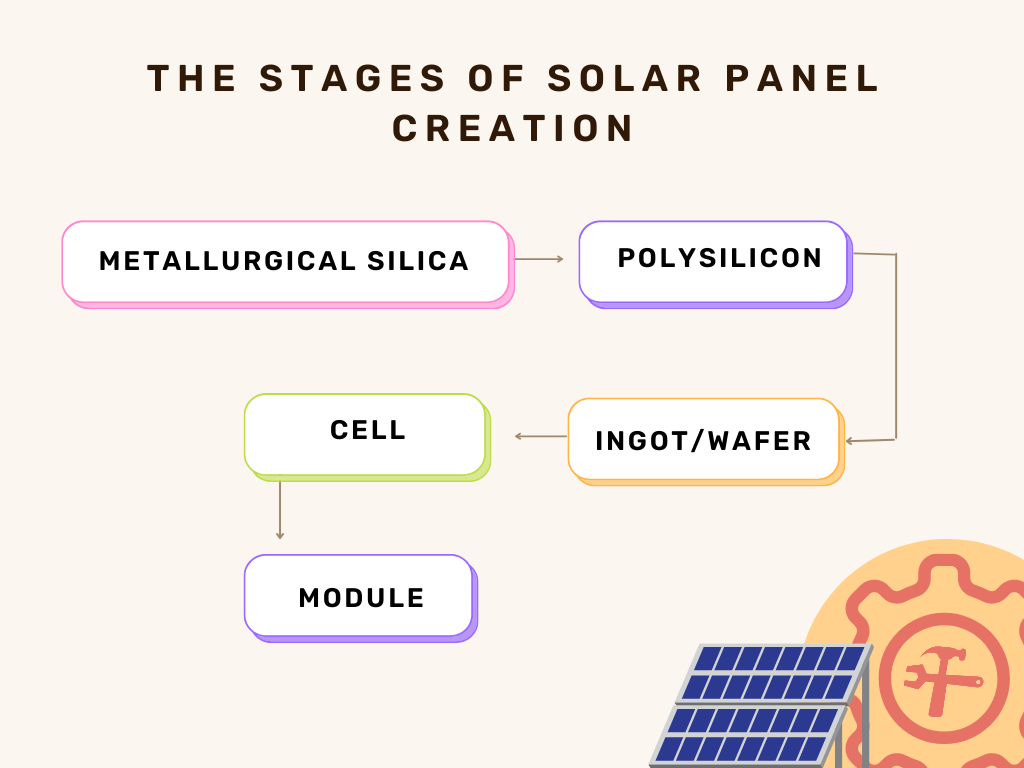

The rationale for a solar PLI is clear enough. India used to import polysilicon ingots and wafers and use them to make cells and modules. With the solar PLI, the country aims to extend backwards and produce polysilicon as well.

Here is what is known. The financial outlay for the PLI was Rs4,500 crore—to be paid out over five years of production. The bid sought to create 10 GW of module capacity. The bid was oversubscribed. Five companies offered to straddle the entire value chain—Reliance New Energy, Adani Infrastructure, Jindal India Solar (a subsidiary of Jindal Polyfilms), Shirdi Sai Electricals and First Solar India. Four firms offered to set up capacities straddling stage 2, 3 and 4. Nine bid for the 3rd and 4th stages.

The chart below shows what happened next. Given the focus on bringing as much of the value chain within India, the bid became a five-horse race between the firms straddling all four stages.

Of these, first solar lost out. It planned to build a smaller facility (3 GW) than the others (who bid 4 GW). A senior manager at a firm that won in the bid told CarbonCopy what happened next. “L1 was Jindal. They asked for PLI support of Rs1,350 crore,” he said. “L2 was Shirdi Sai, it asked for Rs1,870 crore. Reliance was L3, Rs1,920 crore. And L4 was Adani, it asked for Rs3,000 crore.”

In September, 2021, the first three firms were chosen. Given the government wanted three sectoral champions, Jindal and Shridi Sai got all the PLI support they sought, and Reliance got the rest—bout Rs1,200 crore. This, however, wasn’t the final list. In February 2022, Jindal India Solar opted out of the bidding process. Adani gained, becoming L3.

What is the task that awaits these companies? All three winners have promised to produce 4 GW of module capacity. Apart from setting up the facilities for ingots, wafers, cells and modules, they also have to produce polysilicon. “To produce 4 GW of modules, we will need 12,000 tonnes of polysilicon,” said the senior manager, on the condition of anonymity. The catch is: a 12,000-tonne polysilicon plant is not viable. To be on the safer side, as the solar manager said, firms will need a capacity of 26,000-27,000 tonnes. “That will help us produce 9 GW of modules. At such a scale, our price of polysilicon will be $17-18/kg.”

This isn’t enough for exports. Between them, the three solar PLI companies will set up a cumulative capacity close to 90,000 tonnes of polysilicon. This will yield about 27 GW of modules. “By the time these plants come up, India’s domestic demand for modules will rise to 40-50 GW,” said the manager. “All three companies will have to expand their polysilicon plants to supply to other Indian manufacturers. And so, Adani is thinking of trebling its polysilicon capacity to 90,000 tonnes. So is Reliance. As for Shirdi Sai, it is mulling a doubling of polysilicon capacity.” In all, he said, India might see the addition of another 150,000 tonnes in polysilicon capacity.

All three companies—and those who didn’t make it in the first round—are eyeing India’s second solar PLI of Rs19,500 crore. After this, said the manager, India will produce close to 250,000 tonnes of polysilicon each year. Enough to produce 90 GW of solar modules annually.

This is where things get complicated. As CarbonCopy reported earlier, India’s solar sector is struggling. With rooftop solar under attack from DISCOMs and ground-solar dependent on government tenders for growth, the country added 10 GW of fresh solar capacity in 2021.

If this trend continues, most of the solar modules manufactured in the country will have to be exported. Whether they will find buyers depends on efficiency and price. Which, in turn, depends on two factors.

“This experiment of making ingots from polysilicon in India has been tried earlier,” a solar industry executive had told CarbonCopy last year. “A bunch of NRIs had tried this in Andhra under Chandrababu Naidu. DPRs, etc, had been prepared. But the project was ultimately shelved.”

The reasons ran deep. Not only is this manufacturing process energy-intensive—the promoters were hoping for cheap power from gas-based power plants, which proved illusory—the manufacturing of polysilicon comes with its own dynamics. “Sixty percent of polysilicon manufacturing goes into solar cells and the rest goes into semiconductor chips,” the executive had said. “Creating any new material always ends with a graded outcome—in terms of purity.” And so, shipping high quality polysilicon to semiconductors fabs and the rest to module makers, manufacturing units get more profits from semiconductor units and volumes from solar units. “If we are producing only for solar panels, then the economics will not be as good as those of rival plants elsewhere,” said the manager.

At this time, India doesn’t have semiconductor chip making facilities. Those are mostly manufactured by Taiwan, China and Japan. The country, however, is trying to woo the industry. And so, one part of Indian polysilicon’s long-term competitiveness hinges on the success of the country’s semiconductor plans.

The second part depends on relative competitiveness vis-à-vis other countries. As of now, China dominates solar panel manufacturing. The country, as the manager said, makes polysilicon at $12-13 a kilo. While unfair advantage is one part of the answer—four of China’s biggest polysilicon factories are located in Xinxiang, which produces 40% of the world’s polysilicon, and have come under the scanner for using forced labour, another reason is their scale. By 2020, all four companies—Daqo New Energy, Xinte Energy, East Hope Group, and GCL-Poly Energy—were each producing 80,000 tonnes of polysilicon per year from Xinxiang alone. Module-makers like Longi are hoping to push its module-manufacturing scale to 85 GW by the end of this year.

Even if China gets hit by sanctions, other countries are expanding as well. After the Inflation Reduction Act, First Solar decided to set up a 3.5 GW module plant in the US. The company, however, is also setting up a plant in India.

The manager is not too worried about global competition. “If we produce a quality product, we can create an alternative to China,” he told CarbonCopy. “The world badly wants an alternative to China and there is no other country that can work at a similar scale.”

The problem lies elsewhere. To make 26,000 tonnes of polysilicon, a firm will need 40,000 tonnes of metallurgical silica. Making it in house will cost $2 a kilo. Such a plant will cost about Rs1,500-2,000 crore to set up. If imported, it will cost $4 a kilo.

“Some of the winners would prefer to import,” said a solar sector observer, on the condition of anonymity. “They are, however, getting multiple calls from the government asking how they plan to procure metallurgical silica.” This is making them wonder if, in the next round of PLI, firms making their own metallurgical silica will score higher, he said. “Firms already investing upstream and downstream will not want to over-extend.”

The battery PLI

In solar, the technology is established. India is trying to catch up with China on scale and costs.

In batteries, the story is different. While China has a stranglehold on Lithium-Ion batteries—and Lithium—the world is busy innovating alternatives.

Trying to understand how the battery PLI came about, CarbonCopy met Dr. Rahul Walawalkar at his Pune office. The head of India Energy Storage Alliance (IESA), an advocacy organisation for companies working on advanced energy storage, green hydrogen and e-mobility technologies in India, he played a central role in providing industry inputs for the PLI for Advanced Chemistry Cell (ACC) Batteries.

Walawalkar began thinking about domestic battery manufacturing in 2016. “In solar, we were too late,” he told CarbonCopy. “That was not the case with battery storage.” And so, in interactions with government officials, IESA began telling them to focus on batteries because “the global race for advanced battery manufacturing was just starting to take off 5 years back unlike solar”.

Work started in 2017. Given the experience with M-SIPs, support through capital grants was ruled out. PLI was considered better. “A company manufacturing batteries in China will have a cost advantage of $15-20 per kWh due to economies of scale and advanced supply chain,” Walawalkar said. “We needed to give companies a cash incentive which offsets that subsidy and make the market a level playing field to attract investments in India for advanced battery manufacturing.”

That was the arrangement. Industry will set up the plant. The state will erect a barrier against dumping. Industry will get a disability cost for five years.

In this period, as RP Gupta, a former additional secretary in Niti Aayog told CarbonCopy, “India has to carry out taxation reform and ensure major taxes which put domestic production at disadvantage are subsumed in GST, particularly energy taxes.” Failing that, companies have five years in which to build enough scale to become cost-competitive – if they want to export. If not, though, import barriers mean they can sell in the domestic market, even at a higher rate.

Today, companies (pack-makers) import cells from China and assemble them into battery packs. Firms like Chennai-based Labkarts work with customers, choosing the cell suppliers and creating battery solutions for clients. Other firms source their own cells from China and assemble them here. Now, lest India’s oil dependency gets replaced by a cell dependency, the government wanted them to be made in India.

The National Mission for Energy Storage slowly took shape. It was merged with NITI Aayog’s National Mission for Transformative Mobility. 2019-20 was spent on a series of stakeholder consultations to bring industry together to develop a framework for the ACC PLI, which was the 1st PLI drafted by the NITI Aayog team.

Then came Covid. “There was a delay,” said Walawalkar. “Europe got its act together on energy storage faster than us. In 2019, almost all global companies were open for partnerships to get into cell manufacturing in India. Most of them began looking at Europe. We lost those international companies—like LG, Panasonic and Tesla. But on the positive side, many large Indian conglomerates have stepped up similar to how the EU is witnessing many homegrown companies leading the drive to set up Giga factories in Europe.”

In tandem, global thinking about scale changed as well. Countries were suddenly talking about setting up 100 GWh capacities. In India, too, the scale changed. IESA had originally proposed 20GWH manufacturing to be set up by 2020 during the initial concept note proposed in 2016. This was increased to 50GWh by 2025 during the drafting of ACC PLI.

When the ACC PLI tender was announced, some industry experts had wondered if the country would get 50 GWh of bids. The eventual number stood at 130 GWh.

Given the flux in technologies, the government wanted to stay technology-agnostic. And so, bidders were evaluated along projected industry goalposts of cost and quality (energy density/number of cycles). A company which finds its technology turning obsolete, and finds itself slipping behind, was free to switch to another technology. Bids were evaluated on three parameters, Gupta told CarbonCopy—localisation, the quantum of incentive sought, and the time-frame. Winners were announced in March 2022.

The battery PLI throws up three large questions. The first, as in solar, is about backwards integration. “A cell needs cathode, anode, electrolyte and separator,” a former consultant with Freedback Infra told CarbonCopy. “Cathode alone accounts for 40-60% of the cost of the cell. Will the firm manufacturing cells in India have to assemble all of those as well? This will need huge capital—especially if we are talking about exporting to the world.” World over, he said, a few firms control these industries.

The second question is about the government’s capacity to choose the technological leaders of tomorrow. The PLI, allotted Rs18,100 crore by the government, went to four companies—Reliance New Energy Solar (5GWh), Rajesh Exports (5GWh), Ola Electric (20 GWh) and Hyundai Global Motors (20 GWh).

Reliance New Energy Solar is a subsidiary of Reliance Industries. Rajesh Exports raised eyebrows. Despite its raison d’etre lying in gold-refining, the company pipped industry stalwarts like Amara Raja and Exide. The company had offered the highest level of localisation – according to Gupta, he promised 60% localisation in year two. This was, as Business Standard wrote, “more than double of the other competitive bidders”.

These numbers were challenged by other industry players. Speaking to the paper, a senior executive who was not identified said: “The localisation commitments made by them beats me, especially when far more established players say that even in 2030 it would not be more than 50-60%.”

What happens if the company fails to deliver? In one way, the government doesn’t lose since, unlike capital subsidy, the incentive is linked to actual production. The company, as Gupta told CarbonCopy, will instead get penalised for missing its commitments. The country, however, pays an opportunity cost. Its prospects of dominating an emerging industry recede.

Interestingly, one of the institutional investors in Rajesh Exports—with 2.78% shares—is Asia Investment Corporation (Mauritius). Not only has the firm invested in Adani Power and Adani Green, it shares a director with two other Mauritius-based funds—APMS Investment Fund and Albula Investment Fund—that were in the news for investing almost solely in shares of Adani Group firms. Their investments, as Bloomberg reported, have coincided with a rally in Adani Group shares in recent years.

The third company was Ola Electric. Given that firms like Ather and Bounce have done more work on electric scooters, its selection raised eyebrows as well. Scale worked in the firm’s favour. It was planning to produce as many as 2 million scooters a year. “If its scooters do well,” said Walawalkar, “The company will absorb 20-40 GWh of batteries on its own.” To catch up, Ola had acquired Etergo, an e-scooter startup in the Netherlands in May 2020. Those scooters, as press reports said, were launched in India. Ola’s scooters, however, have been beset with complaints about poor quality, including batteries catching fire. In July 2022, three months after winning the PLI, the company said it would set up an R&D centre.

All of which leaves us with Hyundai Global Motors. Indian media went to town saying Hyundai was investing in the country’s battery sector. And then, in July 2022, Hyundai Motor Co and its Indian subsidiary wrote to the government denying any links with its namesake that had applied for the battery manufacturing PLI. As Economic Times reported, Hyundai Motors accused Hyundai Global Motors of “wrongly utilising its trademark, trade name and logo, and making misrepresentations before authorities in the country”.

As of now, the battery PLI has been given to Rajesh Exports, Reliance and Ola.

End game

The PLIs for solar and batteries raise large questions. At a time when global rivals are focusing on a single manufacturing stage, can a firm straddle an entire value chain and be competitive?

Why are firms associated with the same big companies cropping up in relation with both PLI awards instead of others getting in? Are conditions like “scale” and “speed” of manufacturing rollout working as cross-purposes with the need to build competitive advantage around the technologies of the future? Take batteries. “The future is to get away from lithium,” said the former consultant with Feedback Infra. “All those mines are controlled by China. 70% to 80% of the processing of lithium, too, is controlled by China.”

And yet, as he said, creating new batteries like sodium-ion, etc, will take 8-10 years. When the PLI scheme wants a quick rollout, firms working with mature technologies—like lithium ion—are bound to trump firms trying to develop alternatives. And yet, the PLI programme is almost silent on indigenous research.

The final part of our series will get into such questions.

About The Author

You may also like

Loss and Damage Fund board meets to decide on key issues, Philippines chosen the host

India’s new hydel push can’t turn blind eye to Teesta III failures

Teesta disaster: How not to build a dam

World, led by China, added 50% more RE capacity in 2023 than in 2022: IEA report

Renewables, not coal, the energy of choice for investors in India for second year in a row: Report